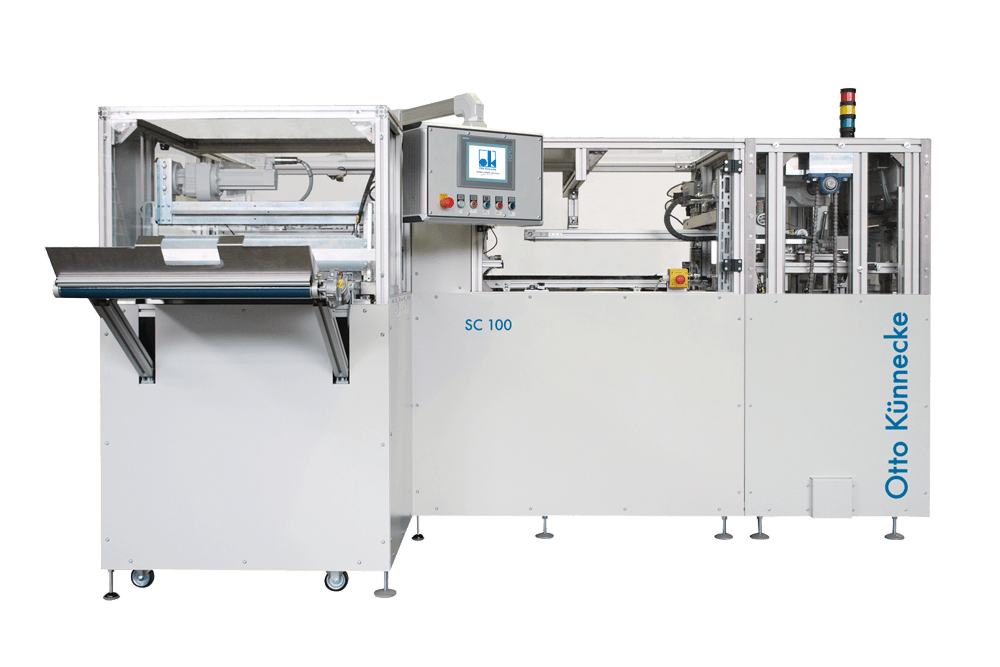

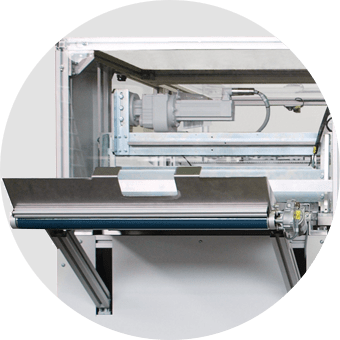

Before the first cutting process in the lateral direction, the sheets are automatically transported to an alignment station which checks the exact positioning of the products by means of optical sensors. This happens with the help of the registration marks or the sheet edges. An electronic guillotine cuts the material and cut leftovers are automatically caught in a waste container. After the onward transport to the second cutting unit, a position check occurs once more by means of optical sensors. The second guillotine divides the material in the longitudinal direction afterwards. Here, also, cut leftovers are automatically collected. Depending to the application, both cutting units can carry out in each case one or several cuts.