Placement Maschines

MB 200 – Intelligent setup for a flexible SMT production

The flexible solution for every High Mix/High Flex production environment with varying batch sizes.

324 feeder slots

- Select feeder lane capacity to suit your requirements: 114, 184, 254 or 324

- Assemble large, complex boards on a single system

- Optional board size up to 800 x 600 mm

More Information

True modular performance configuration

- Configure placement head modules to suit your needs

- Placement performance from 6,000 to 14,400 components per hour (IPC-9850)

- Additional placement head for odd shaped components

High Mix

- Place all component package types with any placement head (flexibility and redundancy)

- No special modifications required

- Automatic tool assignment for each placement head

- Integrated dispenser (optional)

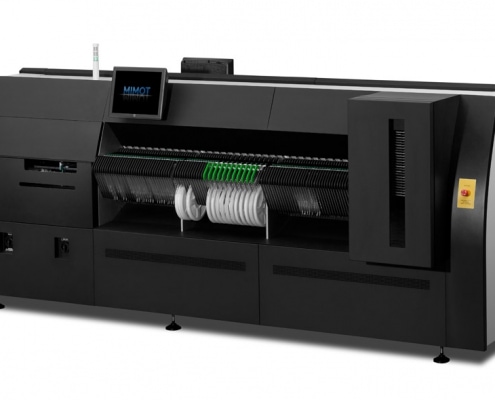

MB 300 – Intelligent setup for a flexible SMT production

The performance-optimized solution for every High Mix/High Volume production environment with varying batch sizes.

Multi level conveyor system

- Intelligent conveying system for undamped throughput (bypass)

- Significant increase in machine performance

- BUILT TO ORDER production in practice

- “Batch size 1” economically feasible

- Patent pending

More Information

Active feeder

- Exchange feeders while the machine is running

- Change setup while the machine is running

- Automated feeder recognition

- LED status indicator

- Special feeders

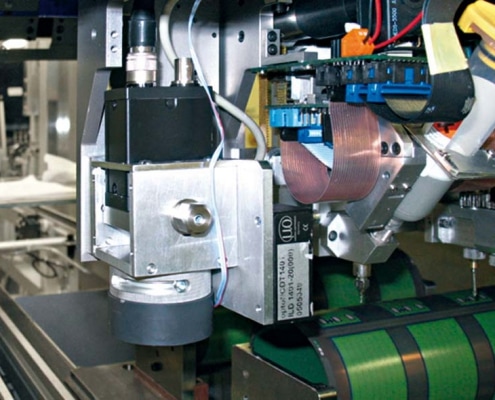

Reflexionsoptik

- Optimized image acquisition at highest speed

- Component size from 01005 to 55 x 55 mm, optionally larger size (multi shot imaging)

- Patent pending

Line

The solution for every High Mix/High Flex/High Volume production environment with varying batch sizes.

High-Mix/High-Flex/High-Volume

Utmost efficiency for varying batch sizes, varying board technology, and a nearly endless variety of component packages.

More Information

Line balancing

Automatic dynamic load-balancing of all placement heads and machines within a line for maximum throughput. The system dynamically responds to changing load balance values.

Feeder capacity

The line features a maximum feeder capacity of 540 slots and allows the use of all types of special feeders.

Board Handling

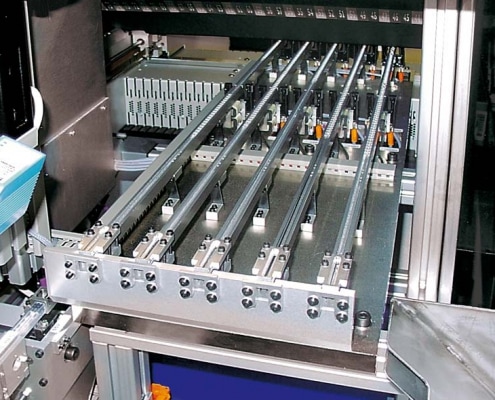

Track MT 60 – Board Handling Modules

MIMOT board conveyor modules are used to interconnect several SMT placement machines and/or additional equipment to create an in-line production line.

The modules are used as in-feed-, link- or out-feed-stations and feature programmable belt speed as well as check and stop functions.

More Information

Je nach Anforderung können verschiedene Kombinationen beliebig zusammengestellt werden. Die Bedienung und Konfiguration erfolgt über den Bestückungsautomaten.

Um eine Verbindung mit anderen Einheiten einer Produktionslinie zu ermöglichen, sind die MT-Module mit einer SMEMA-Schnittstelle ausgestattet.

Die Breitenverstellung für Einlaufbänder erfolgt zusammen mit dem Bestückwagen des Bestückungsautomaten (motorisch, als Standard mittels manueller Eingabe, bzw. optional automatisch via Software über das Bestückungsprogramm).

Zusätzlich kann als Erweiterung eines MIMOT Track MT 150 E/A oder eines MIMOT Track MT 180 E/A ein Inspektionsplatz montiert werden. Er ermöglicht die manuelle In-Line-Prüfung von Leiterplatten im Verlaufe des Transportes von einer Station zur Nächsten.

Mit dieser Option wird ein MIMOT Track MT 60-Modul wie folgt erweitert:

- Ergonomisch konstruierte Arbeitsfläche mit Armauflagen für ermüdungsfreies Arbeiten

- Ablagemöglichkeit für Kontrollhilfsmittel in optimaler Arbeitshöhe

- Lupenleuchte

- Ausleuchtung der Arbeitsflächen

- Programmierbarer Kontrollstep des Leiterplatten-Transportes

Magazine Lifts

The loader magazine lift automatically takes the boards out of the magazine and provides them to the next segment via a conveying belt. The integration of the board extractor into the conveying belt module brings enormous space savings. Magazines can be exchanged quickly and comfortably.

The unloader magazine lift automatically takes the boards from an out-feed belt and stores them in a magazine. The integration of the board pusher into the conveying belt module brings enormous space savings. Magazines can be exchanged quickly and comfortably. Due to the pusher-design, no magazine clearance slots are required below the board.

The magazine lifts can even be operated in reversal mode. Using a combined in-feed/out-feed belt segment, boards can be taken out of a magazine slot for placement operation and after assembly they get pushed back into the magazine via the same belt segment.

Magazine Lift TWIN

The MIMOT board magazine lift TWIN can be operated either as loader or as unloader or for bidirectional loading/unloading from one end of the line.

Due to its high loading and unloading capacity it is perfectly suited for lightly-manned shifts or if pass and fail boards are to be separated automatically.

Destacking Unit

The MIMOT board destacking unit is designed to add to MIMOT board magazine lifts. This unit permits loading of an assembly line with stacked boards. Using the MIMOT board destacking unit customers can automate the expensive and time consuming task of manually separating piled-up boards.

Can be combined with standard and TWIN loaders. The destacking unit doesn’t require extra footprint.

Rotation Station

The MIMOT board rotation station allows for changing the transport direction e.g. by 90 degrees. Key benefits are improved area utilization, better overview over the entire line and increased efficiency through minimized legwork.

Combining two assembly lines into one reflow oven or separating PASS/FAIL boards after an AOI inspection are just a few possible applications of the rotation station.

Buffer Station

The MIMOT board buffer station provides temporary first-in first-out (FIFO) storage of boards within a production line.

To ensure communication with SMT placement machines the magazine lifts are equipped with SMEMA interfaces.

Feeder

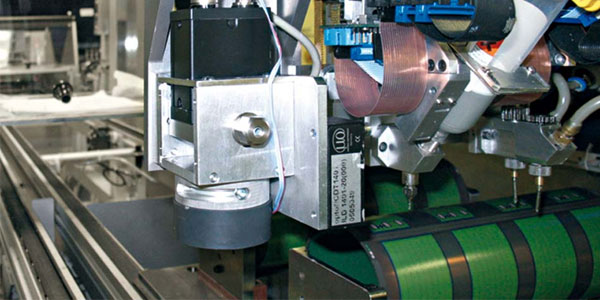

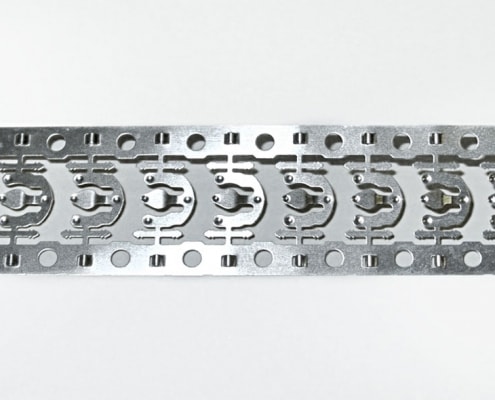

Triligent Tape Feeder

The TRILIGENT tape feeder ensures simple setup change. You can insert the mounted feeder(s) into any slot while the machine is running. The machine recognizes the feeder, the mounted component and the position.

Repetitive errors are virtually ruled out as feeder and components are coded.

Mehr Information

Tape feeders are available for all common tape widths (8 to 88 mm) and reel sizes. In addition, special editions of tape feeders are available for components up to 12 mm height (deep blister pockets).

Following versions are supplied as standard:

- TRILIGENT tape feeder 8 mm, d = 380 mm

- TRILIGENT tape feeder 12 mm, d = 380 mm

- TRILIGENT tape feeder 16 mm, d = 380 mm

- TRILIGENT tape feeder 16 mm, d = 380 mm (for deep blister pockets)

- TRILIGENT tape feeder 24 mm, d = 380 mm

- TRILIGENT tape feeder 24 mm, d = 380 mm (for deep blister pockets)

- TRILIGENT tape feeder 32 mm, d = 380 mm

- TRILIGENT tape feeder 44 mm, d = 380 mm

- TRILIGENT tape feeder 56 mm, d = 380 mm

- TRILIGENT tape feeder 72 mm, d = 380 mm

- TRILIGENT tape feeder 88 mm, d = 380 mm

Triligent Vibration Feeder

At the TRILIGENT vibration feeder V8 the components are vibration-forwarded within the exchange bar to reach the pick position. At the TRILIGENT vibration feeder V32 the components are vibration-forwarded onto the presentation plate where they reach the pick position. At the V24 size both concepts are possible.

More Information

The following feeder versions can be supplied:

- TRILIGENT vibration feeder V8

- TRILIGENT vibration feeder V24

- TRILIGENT vibration feeder V32

Triligent Label Feeder

The TRILIGENT label feeder provides automated labeling of boards, sub-panels or components (e.g. EPROMs) by the placement machine. Among the wide range of possible applications for this feeder type are e.g. placement of labels to cover vias during the soldering process or attachment of ID labels on boards and components.

More Information

The labels (barcode, Data Matrix, etc.) are fed on a carrier tape like taped components.

Vacuum nozzles are used for placement. Presence and position of the label is checked and aligned by the vision system to ensure precise, repeatable attachment on the board.

Setup procedure is exactly the same as for standard feeders. The placement machine automatically recognizes the slot where the label feeder is inserted.

Feeder Cart

The MIMOT feeder cart is used for proper, careful and clear storage of MIMOT feeders. Special feeder carts are available for the innovative TR feeders with their continuous data connection to the MIMOT prep software and the placement machines.

Whether feeders are inserted in placement machines or are stored in feeder carts, operators can use the Prep PC or the screen of the placement machine to see, where individual feeders are located and what components are mounted on.

What’s more, the various indication possibilities of the triple LED on each feeder remain active when the feeder is stored at the feeder cart. When searches are run, the feeder will respond by flashing the according LED – even when stored at the feeder cart.

Setting up the machine is optimally supported per software: The LED of the feeder to be inserted flashes – the LED of the target slot of the machine flashes – even if the feeder is stored at the feeder cart. Fast and optimized. It’s that simple!

More Information

The following types of feeder carts are available:

- TR feeder cart “master” containing one level of approx. 1 x 72 “S8” feeder slots

- TR feeder cart “master” containing two levels of approx. 2 x 72 “S8” feeder slots

- TR feeder cart “slave” containing one level of approx. 1 x 72 “S8” feeder slots

- TR feeder cart “slave” containing two levels of approx. 2 x 72 “S8” feeder slots

Feeder carts without connection with the Prep PC or the placement machine are also available:

- Feeder cart “master” containing two levels of approx. 2 x 77 “S8” feeder slots

- Feeder cart “master” containing two levels of approx. 2 x 64 “S8” feeder slots

- Feeder cart “master” containing three levels of approx. 3 x 64 “S8” feeder slots

Feeder Mounting – Feeder Jig

The special feeder jig for TRILIGENT feeders significantly facilitates component mounting and adjustment of the feed unit of TRILIGENT tape feeders.

After the feeder is inserted into the jig the operator has both hands free to conveniently mount the reel or the stick on the feeder. The inclination of the jig can be adjusted continuously.

The integrated power supply enables simple mounting and dismantling of feeders.

Feeder Setup – Setup Station

Ergonomic workplace for typical setup operations like data entry, component storage, mounting and dismantling of feeders, optimization of placement programs.

More Information

- Conductive work surface (ESD protection)

- Storage space for Prep PC, barcode scanner and barcode printer

- Feeder jig can be fixed in two angles of inclination

- Comfortable user interface via touch screen display

Special Solutions

Automated LED assembly (SMD LEDs, PIRANHA LEDs)

- Automated feed (LED clustering)

- Component batch verify

- Online refill

- Automated polarity recognition

More Information

Bending and cutting device

- Integration of bending and punching devices on demand

- Automated tool exchange

- Automated reel monitoring

- Relational assembly possible

3D (MID) placement and dispensing

- 3D placement and dispensing possible

- Integration of special conveyor systems

- Integrated solder paste dispenser

Special Solutions MB 200 / MB 300

Reject feeder

- Space to discard components

- Can be installed in any machine slot

- Component level monitoring

Surftape feeder

- Placement of DIEs of various sizes

- Feeder position can be arbitrarily chosen

- Usable with all placement heads

More Information

Feeder with background illumination

- Includes background illumination

- Relative centering of components

- Feeder position can be arbitrarily chosen

Software

MIMExplorer

Learn more about the modular MIMExplorer, the intelligent software solution for managing processes in eletronics production from incoming goods, via storage, automatic inventory and all relevant information.

Joining forces for innovation and progress

Otto Kuennecke Customer Service GmbH from Holzminden took over the research and development as well as the service department of Mimot GmbH from Loerrach on March 1st, 2021. With this step, the innovative mechanical engineering company and software developer intends to develop smart storage and picking systems in the SMT and electronic manufacturing sectors with increased know-how and product expertise, thus enriching the market with innovative solutions…

Do you have any questions? We are happy to talk to you at any time. Write us a message or just call us. We look forward to your inquiry!

Otto Künnecke GmbH

Bülte 1

37603 Holzminden

Germany

Sales-Team

Fon +49-5531-9300-888

sales@kuennecke.com