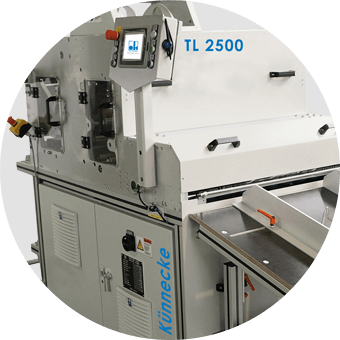

TL 2500

Tape layer system for the production of overlay foils/films

The TL 2500 tape layer produces overlay films with magnetic stripes or other security features. The finished product is picked up either as an endless material on spools, or dispensed in single sheets. Depending on the configuration, up to 12 tapes at the same time can be applied onto all industry-standard overlay films. During the process, the tape is applied with maximum security to the substrate, and the carrier material is removed and automatically rewound on a single spool for easy disposal.