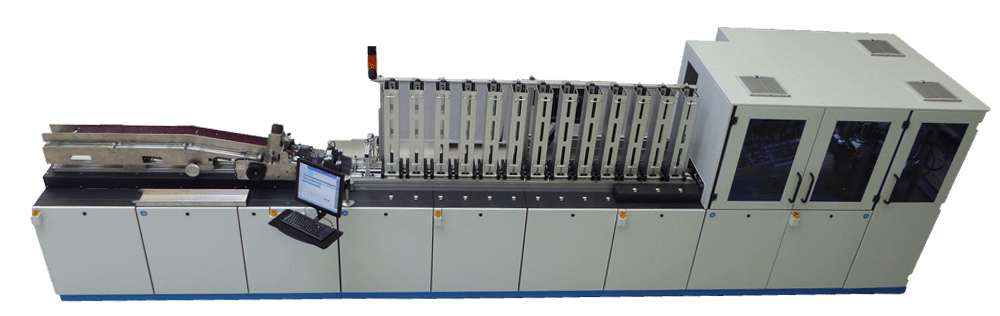

For many uses it can make sense to sort passports according to given parameters like postal code, receiver’s branch of a registration office or, for example, to the country of destination. With a manual sorting, the potential for errors is high and the processing security is comparably low. Hence, a manual sorting is often carried out with the help of the four-eye principle involving additional personnel and causing extra expenditure. However, a fully automatic sorting prevents wrong groupings, offers maximum security, and holds personnel costs down. Our system can be configured flexibly and selectively for individual sorting and grouping tasks.