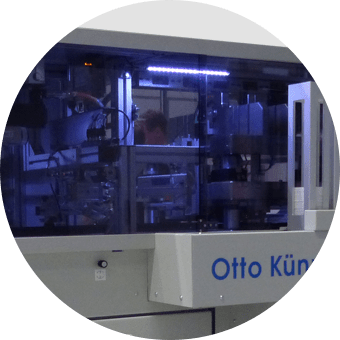

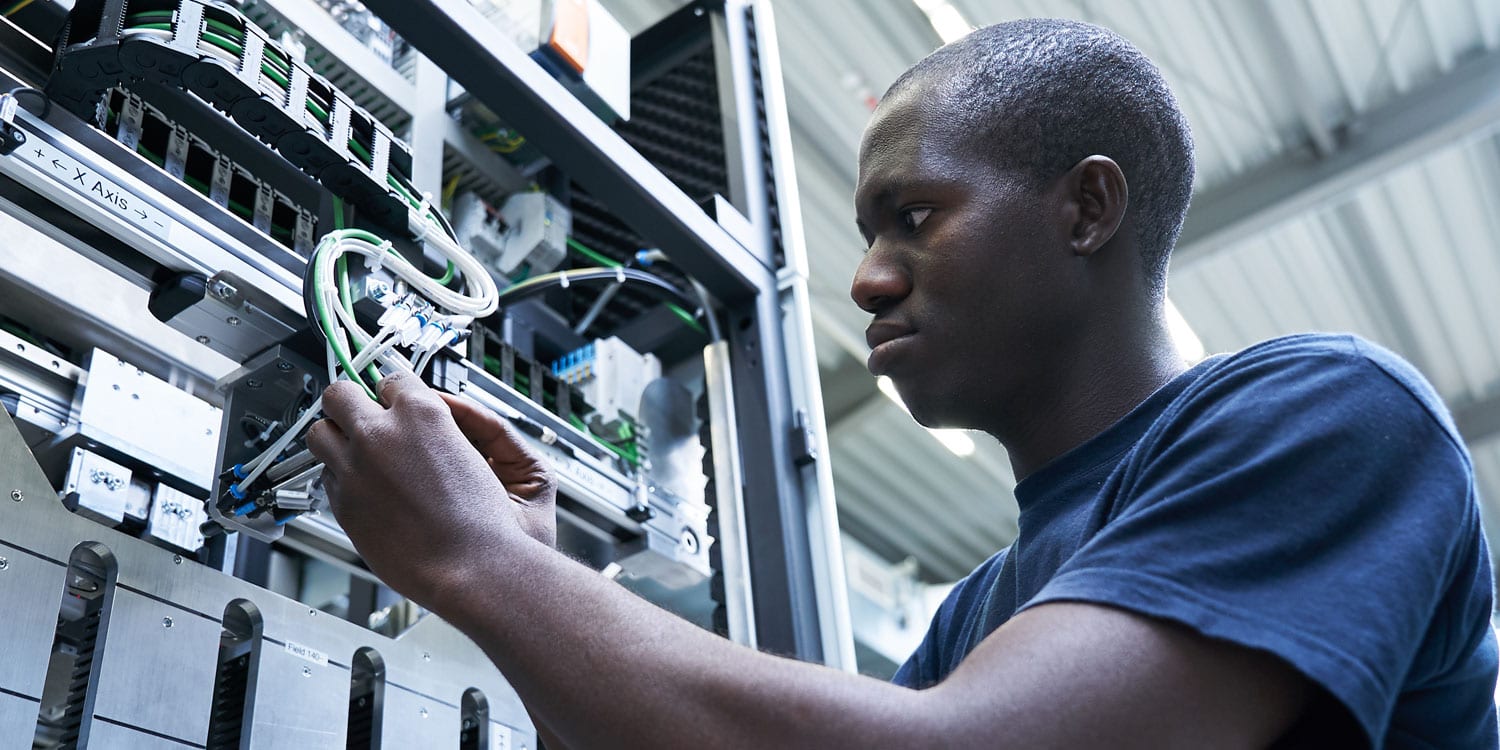

KS 104

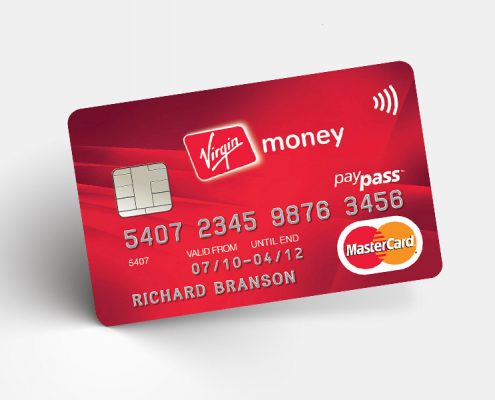

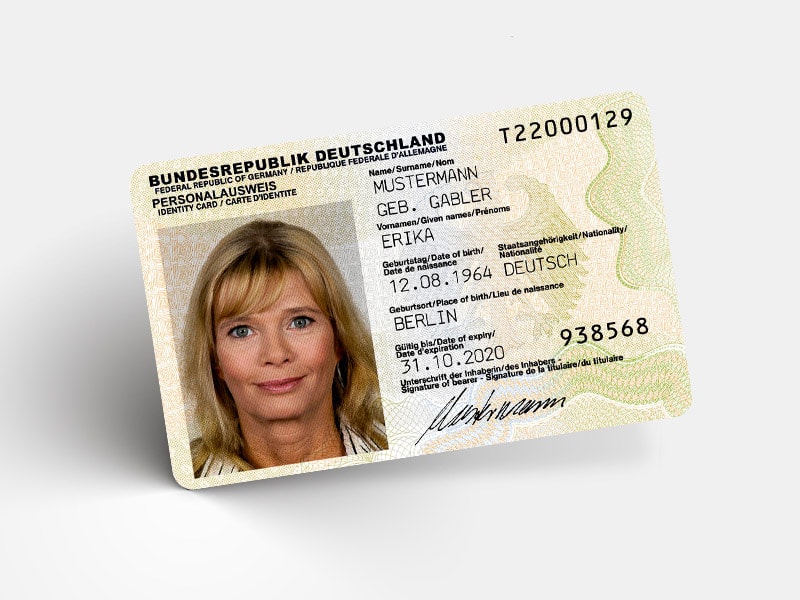

Fully automatic card punching system

The KS 104 unites the highest production standards with high speed, precision and reliability. The optimum system of high throughputs is convincing with its unique sheet feeder for the fully automatic processing of sheets directly after laminating or printing and without the need for cutting the cards or strips.