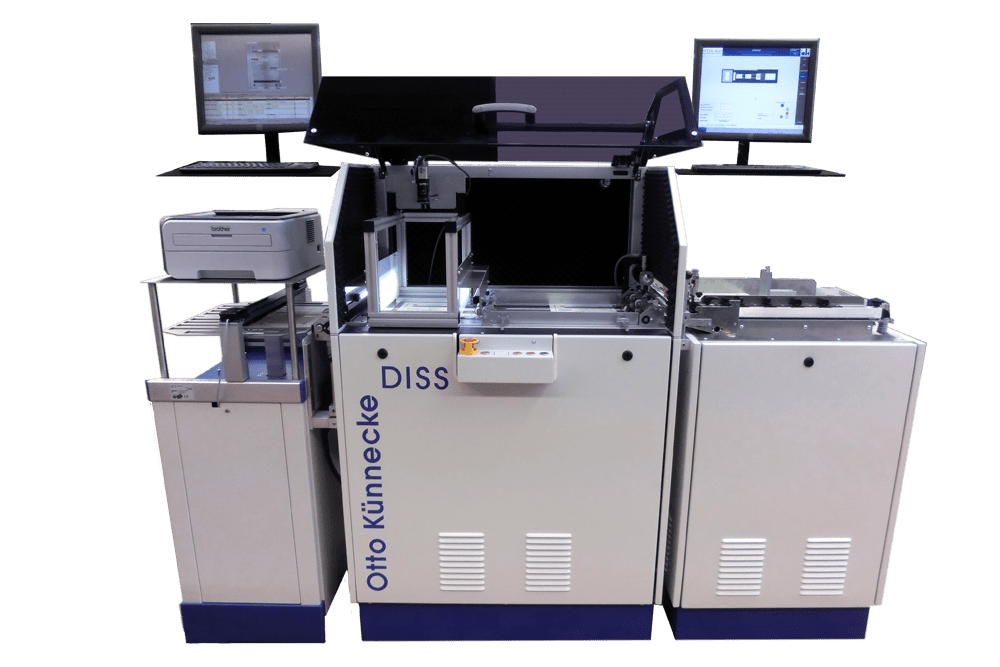

Watermarks, UV printing, infrared printing, holograms or security numbering are only some of the security signs which are becoming more and more innovative in order to protect sensitive documents like birth certificates, licenses, visas or financial documents against forgery and abuse. Hence, during the production, subsequent treatment or personalization of such documents, a steady monitoring of these security features is essential to guarantee their genuineness. With the DISS we have developed a modular system which checks security elements reliably and which as well can recognize and reject damaged or incorrect documents. Afterwards these documents can be sorted or be selectively stored temporarily in groups. Moreover holograms or labels can be applied with various additional modules, or automatic packing lists can be made up for accumulated document groups. Also different modules are available for packaging and mailing preparation. With its high degree of the automation in all processing steps, the DISS is the ideal solution for the processing of high security documents.