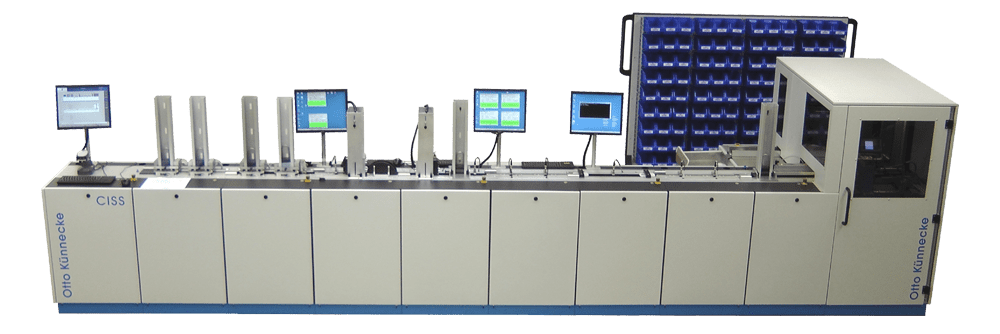

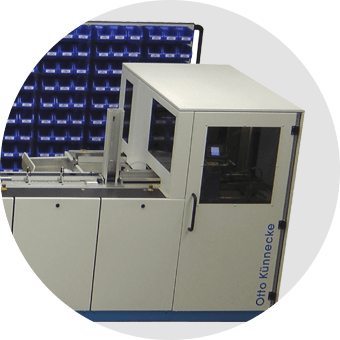

CISS

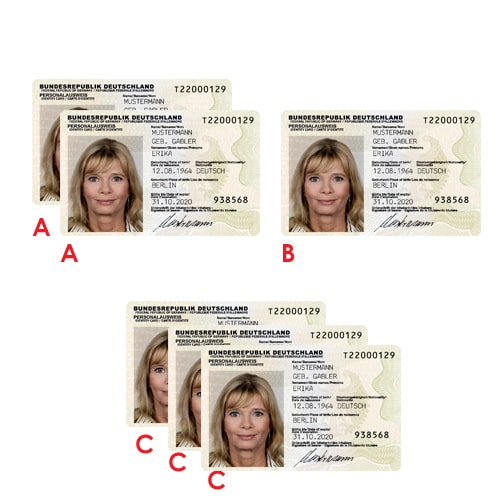

Examining, sorting, recording, counting, and doing a lot more – securely and automatically.

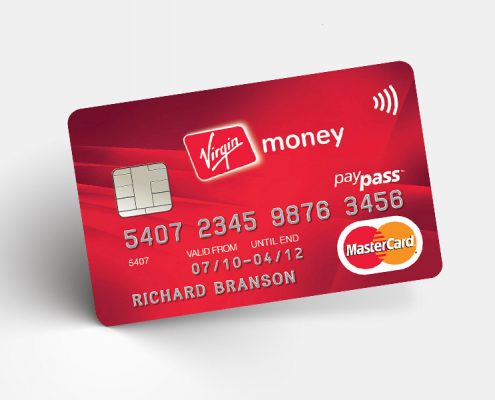

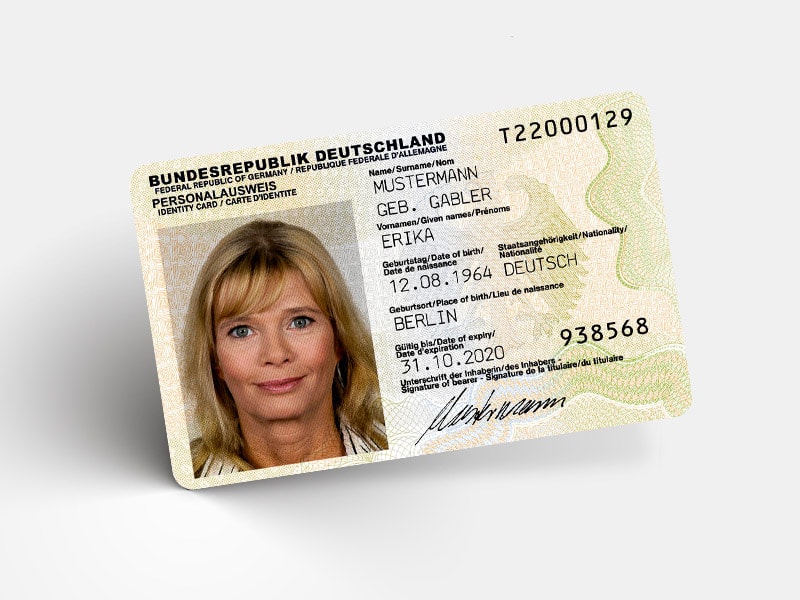

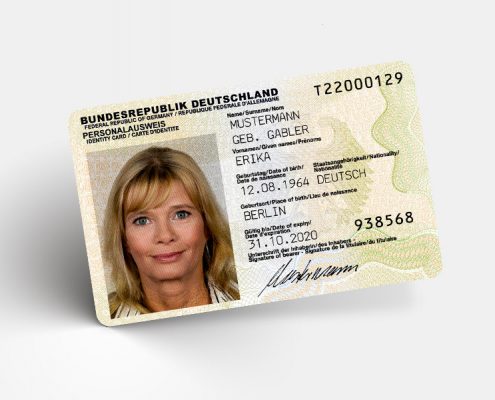

The more working steps which are carried out automatically in the card processing, the lower the rate of mistakes. Following this simple principle, we have developed an identification and sorting system which has no equal with regard to efficiency and security. Before or after the personalisation of the cards, there are many and various application possibilities for security relevant automation.