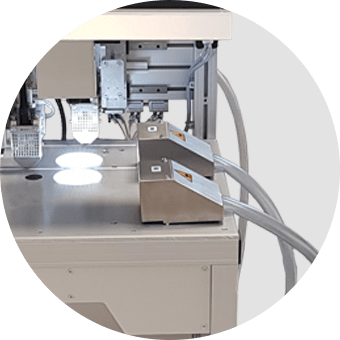

The operator puts the overlay and core films, with or without safety features or magstripe, on the co0llation table. An exact positioning is ensured thanks to three or four positioning pins the travel position of which can be fixed by individual programming. By means of a high-resolution video system with up to four cameras, the operator can exactly check the sheet positions and if necessary correct them. A halogen cold light source provides for good visibility of the fixing unit which is particularly helpful with the first layer to be processed since it is usually positioned face-down. During the whole collating process, an uninterrupted thickness measurement is carried out which tells the operator how the thickness of the film set has changed after every single application of another film. Thus mistakes can be curtailed and false collations be avoided.