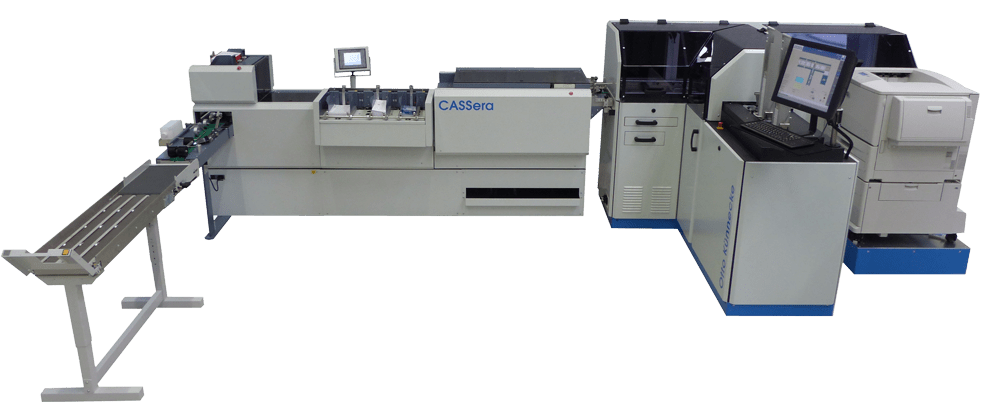

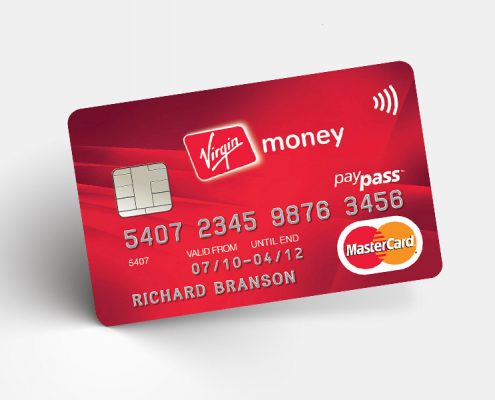

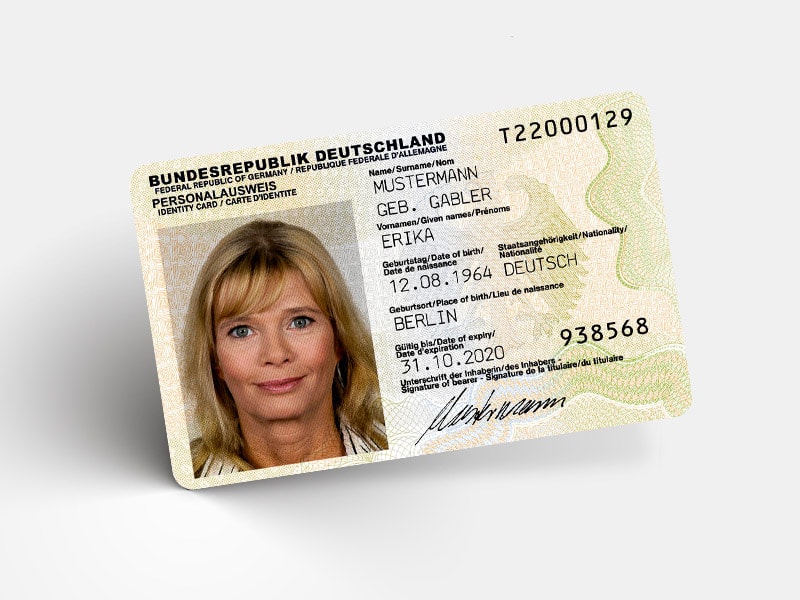

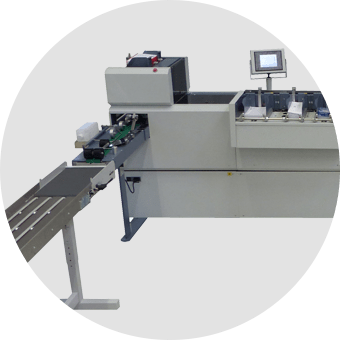

The inserter accepts one, or several, forms with or without cards from the pre-selected feeder canal. Several forms, also different forms, can be collected together for the same receiver and inserted as a batch (e.g., covering letter with card + an invoice). Furthermore, additional enclosures can be added to the forms, such as flyers, retour forms, terms of trading etc. before they are inserted. With the help of sensors, the processed products are monitored further to guarantee complete track & trace. Faulty arrangements are thus recognised and rejected.