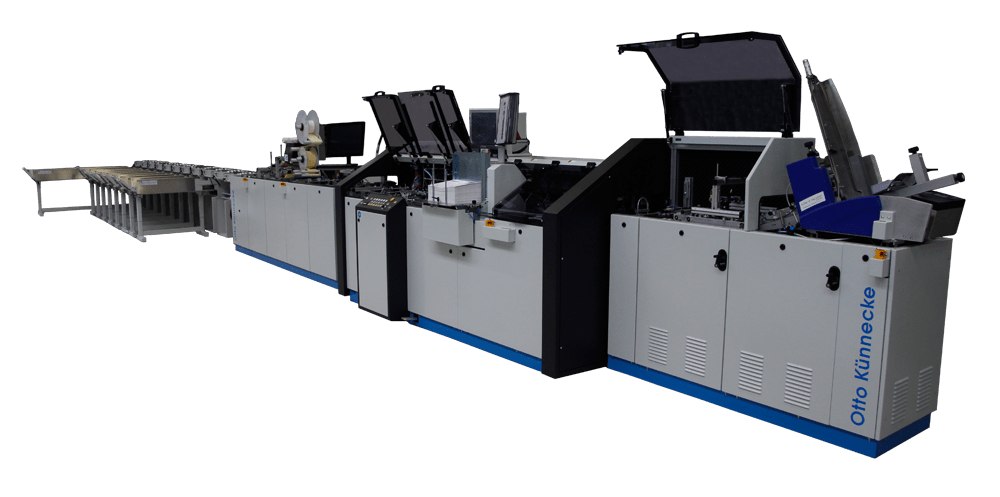

Enclosure station

Insurance policies, trading terms and conditions, receipts, advertising flyers and other enclosures can be added selectively to the remaining documents in the insertion station. Variable possibilities regarding the choice of insertions, supported by a comparison with input data in the database, permit a flexible and purposeful optimisation of this process. Thus personalised or non-personalised insertions can be combined as desired and be put together intelligently.

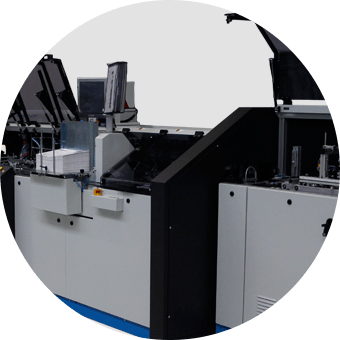

Inserter

During the inserting procedure, the accumulated documents are inserted into the hardcover envelopes which are then closed by means of cold glue.

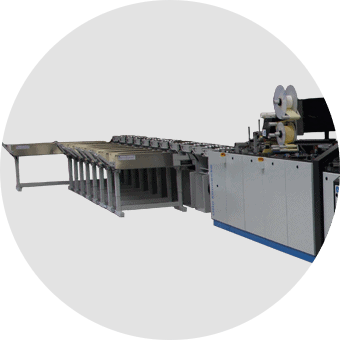

Final processing

In the final processing, variable possibilities for intelligent subsequent treatment are available. After the application of an address label, various control mechanisms ensure that only flawless envelopes are transported to the next conveyor belts. These controlling options range from an integrated weighing scales, to cameras or sensors that check the measurements of the filled and closed envelopes. In the last step of the post-processing, the finished envelope can be sorted or grouped according to agreed factors such as, for example, their weight, postal code, receiver’s branch, country of destination, or for special delivery by courier service. Optical aids like coloured markings, or dividing labels, make the collected groups on the conveyor belt recognizable.

- Selective insertion and treatment of mailings

- Innovative quality inspections to avoid false dispatch

- Fully automatic enveloping at the highest security level

| Throughput | Up to 4.000 envelopes/hour |

| Operators needed | 1 |

| Envelope formats | C4/C5 |

| Max. insertion thickness | 16 mm standard (up to 25 mm optional) |

| Footprint | Flexible |

| Temperature/Humidity | Optimal: 20-25°C room temperature, 60 % relative humidity |

“Die C4 Rigid Mail creates a new benchmark for intelligent inserting. The reliable system allows easy postage optimization and complete product safety.”

Jens Reichardt, service technician

Do you have any questions? We are happy to talk to you at any time. Write us a message or just call us. We look forward to your inquiry!

Otto Künnecke GmbH

Bülte 1

37603 Holzminden

Germany

Sales-Team

Fon +49-5531-9300-888

sales@kuennecke.com