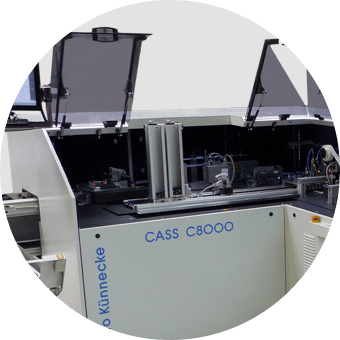

CASS C8000

Mailing system for maximum performance.

With a speed of up to 8000 cycles per hour, the CASS C8000 is our strongest mailing system. Whether as a hybrid multi-talent or as an individually configured specialist with the option for later enlargement: customer wishes can always be moved adaptably and reliably with the C8000. The user-friendly operation of this machine, and its enormous versatility, round off the profile of this performance giant.